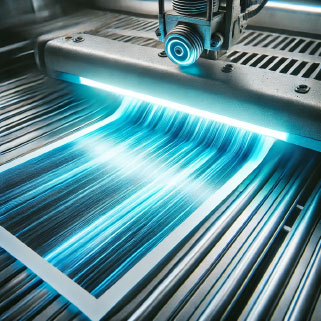

UV LED Print Drying on Plastic

Fast, Efficient, and High-Quality Curing Solutions

UV LED print drying (also called UV LED curing) is a technology that uses high-intensity ultraviolet light to instantly cure inks, coatings, and adhesives printed onto plastic substrates. Unlike traditional mercury lamps, UV LED systems generate minimal heat, making them ideal for sensitive plastic materials such as PVC, PET, PP, PE, polycarbonate, acrylics, and more.

This method delivers fast drying times, excellent adhesion, and durable print quality, even on non-porous plastics that typically resist conventional ink absorption.

LED UV curing is already widely recognised for its increased energy and waste reduction, but PureCure™ Eco UV LED goes further still with lamps that are mercury and ozone free and can operate at up to as little as 20% of the energy of conventional UV lamps. PureCure™ Eco UV LED lamps also have a lifetime up to 20 times that of other market UV systems, they produce no consumable waste and are far safer and operator efficient.

UV LED lamps cure inks within milliseconds, enabling high-speed printing lines and reduced production time.

Plastic substrates are prone to warping, shrinking, or surface distortion under heat.

UV LEDs operate at low temperatures, preventing damage and ensuring consistent results.

UV LED inks are formulated to bond effectively with smooth plastic surfaces, improving:

Scratch resistance

Chemical resistance

Outdoor durability

Color vibrancy

Cost savings

Plastic substrates are prone to warping, shrinking, or surface distortion under heat.

UV LEDs operate at low temperatures, preventing damage and ensuring consistent results.

Faster production

The PureCure™ Eco LED UV System for Heideleberg printers

The PureCure™ Eco LED UV system offers Flexo and offset Heideleberg printers the ability to easily add on retro-fit Eco LED UV curing to most models of Flexo and traditional offset Heideleberg presses, quickly adding affordable, flexible, inline high speed curing to their existing processes.

PureCure™ Eco LED UV is affordable, energy efficient and highly eco-friendly, increasing productivity and job turnaround speeds allowing Heideleberg printed projects to move on to finishing processes much quicker.

PureCure™ Eco UV LED produces real job cost savings and profitability for users via reduced energy consumption & reduced sheet wastage and even allows the re-use of make-ready sheets.

PureCure™ Eco UV LED system is cleaner, removing the need for varnishes and sealers and removing material & print area contamination issues associated with spray powders

Key Benefits

Can be retro-fit

energy efficient

Eco-Friendly

increases productivity

reduced sheet wastage

Most efficient curing

Easy Maintenance

3. Superior Adhesion on Non-Porous Plastics

UV LED inks are formulated to bond effectively with smooth plastic surfaces, improving:

Scratch resistance

Chemical resistance

Outdoor durability

Color vibrancy

4. Energy-Efficient and Eco-Friendly

UV LED systems consume up to 70% less energy than mercury UV lamps and contain no ozone-producing emissions or hazardous materials.

5. Long Lamp Life and Lower Maintenance

LED lamps last 10,000–20,000+ hours, offering predictable performance and minimal downtime.

Best Plastic Materials for UV LED Print Drying

UV LED curing performs exceptionally well on:

PVC (rigid + flexible)

PET / PETG

PP / Polypropylene

PE / Polyethylene

ABS

Acrylic (PMMA)

Polycarbonate (PC)

** Vinyl films**

Lenticular plastics

Surface pre-treatment (corona, plasma, or flame) may enhance adhesion for some lower-surface-energy plastics, especially PP and PE.

Industries Using UV LED Print Drying on Plastic

Packaging & Labels

Bottles, containers, shrink sleeves

Flexible packaging

High-gloss labels

Industrial & Electronics

Appliance covers

Switch panels

Automotive plastics

Signage & Display

POP displays

Backlit signage

Rigid plastic boards

Promotional Products

Plastic pens

Phone cases

Personal accessories

Advantages Over Traditional UV Mercury Lamps

UV LED Drying

Lower heat output

Instant on/off

Longer lifespan

Energy efficient

No warm-up time

Environmentally safer

Traditional Mercury Lamps

High heat generation

Shorter bulb life

Contains mercury

Requires warm-up and cool-down

Higher energy usage

Technical Considerations for UV LED Curing on Plastic

Wavelength Selection

Typical wavelengths:

365 nm

385 nm

395 nm

405 nm

Most UV LED inks for plastic cure best between 385–395 nm.

Ink Compatibility

Use UV LED-curable inks specifically designed for:

Rigid plastics

Flexible plastics

Thin films

Surface Treatment

For difficult substrates like PE or PP, adding corona or plasma treatment improves adhesion and durability.

Intensity & Distance

Optimize lamp intensity (mW/cm²) and working distance to maximize curing depth and ink hardness.

Frequently Asked Questions (FAQ)

Will UV LED heat damage plastic materials?

No—UV LEDs run at much lower temperatures than mercury lamps, making them safe for heat-sensitive plastics.

Is UV LED ink safe for food packaging?

Yes, when using food-safe UV LED inks specifically formulated and certified for indirect food contact.

What printing methods support UV LED drying?

Digital/inkjet

Flexographic

Screen printing

Offset printing

Optimize Your Plastic Printing with UV LED Drying

UV LED print drying delivers unmatched speed, efficiency, and quality for printing on plastic substrates. Whether you’re producing packaging, signage, or industrial components, UV LED curing ensures fast-drying, durable, and vibrant results with reduced energy consumption and production costs

Does UV LED curing work on all plastics?

Most plastics are compatible, though some low-surface-energy plastics may require pre-treatment for optimal adhesion.